Call us on 01332 864455

ST-38

Information

The ST-38 is the ideal sliding head solution for complex mill-turn parts within the 42mm diameter range. Star’s flagship model is packed with functionality that enables challenging parts to be processed in one set-up.

Three 10 station turrets allow up to 70 tools to be loaded, each tool can be easily removed with Star’s unique clamping mechanism permitting fast set-up changes. The main spindle’s lower turret includes an independent Z3 axis. This axis allows two different features to be machined simultaneously (Z1 + Z3) using Star’s “super-position” control mode.

An independent turret is utilized on the sub-spindle where components up to 150mm can be processed and front ejected. STAR MOTION CONTROL is also included to minimize idle time and thus further reduce cycle time.

WORKPIECE |

||

|---|---|---|

| DIAMETER | 38mm / 42mm (OPT) | |

| LENGTH | 350mm | |

| GEOMETRY | ||

| C AXIS | MAIN + SUB SPINDLE | |

Benefits

- Standard machining diameter 38mm (42mm optional)

- Z1 Stroke of 350mm

- Twin turrets on main spindle for balanced turn-mill operations

- Powerful 11.0 Kw main spindle

- Z3 axis enables SUPER-POSITION control for increased overlap

- YA2 axis on sub-spindle enables off-center pick up

- Tool pre-setter included for easy tool set-up

- STAR MOTION CONTROL to minimize idle time

- Independent turret for sub-spindle for maximum overlap

Specification

| MAIN SPINDLE SIDE | |

|---|---|

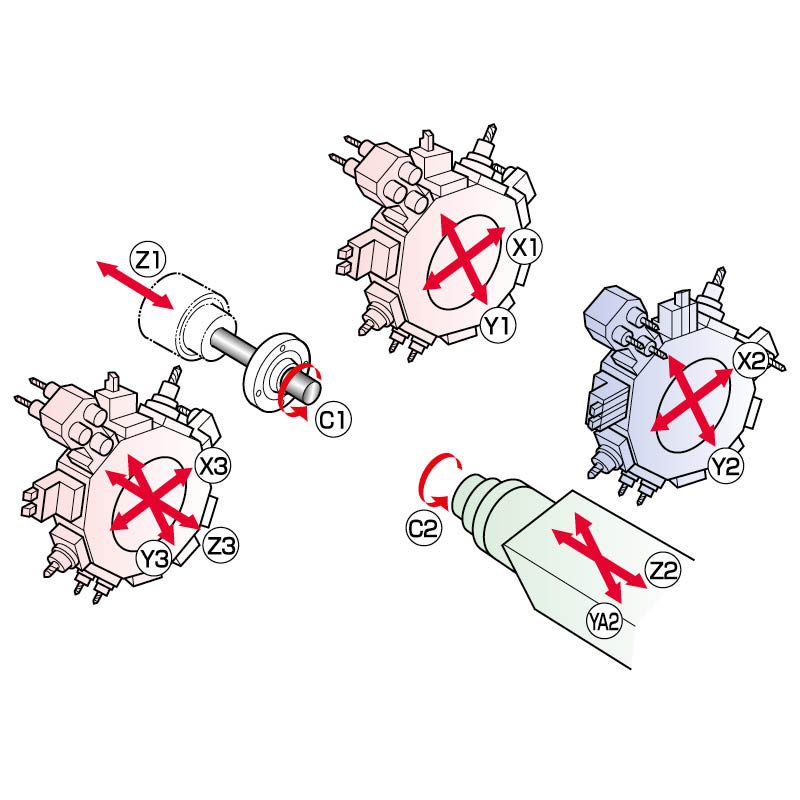

| Number of axes | 12 |

| Main spindle (headstock) | Z1 / C1 AXIS |

| MAIN SPINDLE TURRETS | X1 / Y1 / X3 / Y3 / Z3 AXIS |

| MAX MACHINING DIAMETER | 38 MM / 42 MM (OPTION) |

| HEADSTOCK STROKE) | 350 MM |

| MAIN SPINDLE POWER | 11.0 KW |

| MAIN SPINDLE SPEED | 7,000 rpm |

| MAIN SPINDLE TOOLING | |

| Turning tool | 16 MM SQ + 20 MM SQ (CUT-OFF) |

| TURRET SLEEVE HOLDER CAPACITY | Ø 22 MM SLEEVES (ER16) + Ø 32 MM SLEEVES (ER20) |

| MAX DRIVEN TOOL (PDT) POWER | 4.0 KW |

| MAX (PDT) SPEED | 5,700 RPM |

| KINEMATIC DIAGRAM |

|---|

|

| SUB SPINDLE SIDE | |

|---|---|

| Sub spindle | X2 / Y2 / Z2 / C2 / YA2 AXIS |

| Max. chucking diameter | 38 MM / 42 MM (OPTION) |

| SUB SPINDLE POWER | 7.5 KW |

| SUB SPINDLE SPEED | 7,000 RPM |

| SUB SPINDLE TOOLING | |

| TURNING TOOL | 16 MM SQ |

| TURRET SLEEVE HOLDER CAPACITY | Ø 22 MM SLEEVES (ER16) + Ø 32 MM SLEEVES (ER20) |

| MAX DRIVEN TOOL (PDT) POWER | 4.0 KW |

| MAX SPINDLE (PDT) SPEED | 5,700 RPM |

| FMB | BAR FEED DIMENSION A (MM) | ||

|---|---|---|---|

| Turbo 5-65 | 4416 (3.2M) | 4516 (4.2M) | 7416 (6.2M) |